Sino

WHAT WE DO

As customers' partner

About Us

Text about our company

SINO TECHFULL

is customer’s reliable partner in the following services:

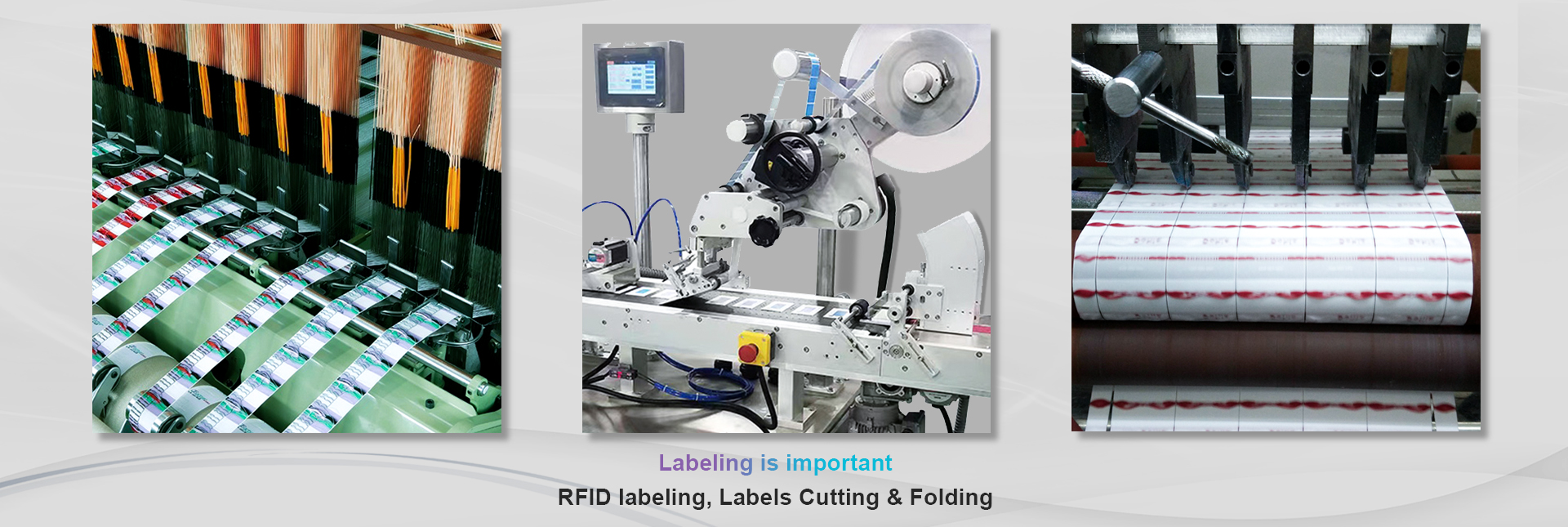

- Based on the expertise and experiences accumulated in the practices for decades we supply machines with technical solutions to customers for narrow fabric manufacturing, which starts from warping, thread covering and winding, to various types of weaving and narrow fabric finishing.

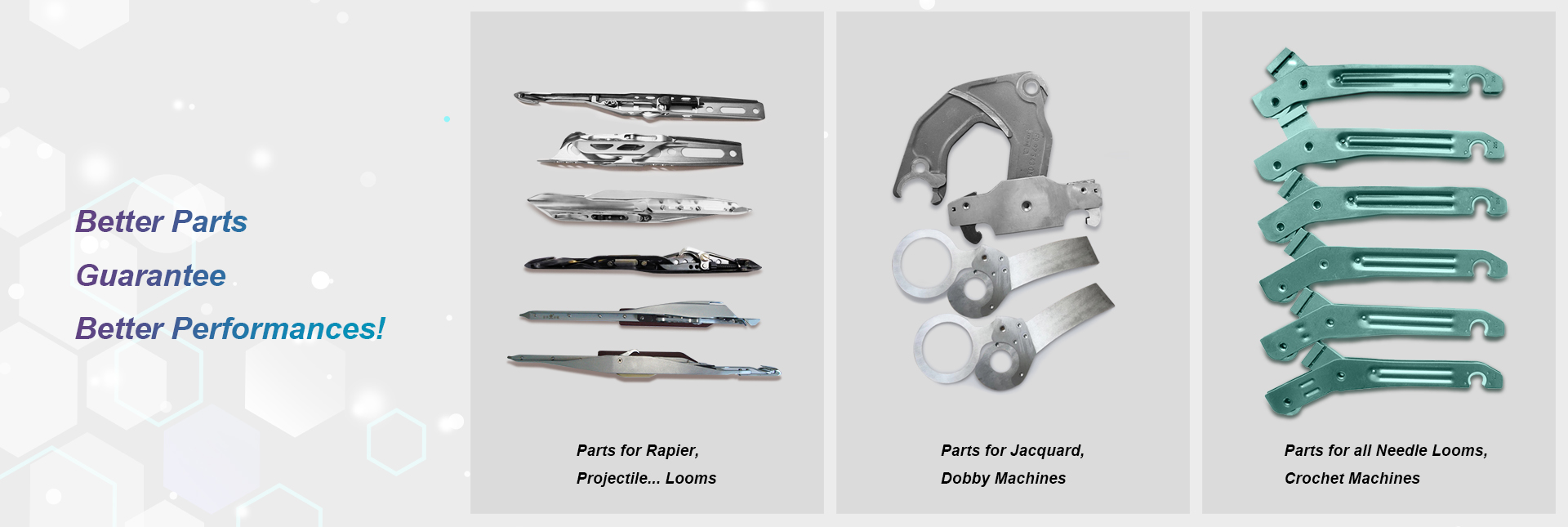

- Supported by the first class manufacturing facilities and backed by the team of conscientious engineers and technicians we supply to our customers the first class quality spare parts for their broad or narrow fabric looms, we take it devotedly as One-Stop Service to save customers from the fiddly jobs of acquiring various items from various suppliers and to keep the quality maintaining uniform and stringent technical standards.

videos

New Products

-

Computerized electronic Jacquard loom with 960 hooks

Computerized electronic Jacquard loom with 960 hooks, equipped with electronic take-up, electronic weft feeding, electronic warp feeding

-

Automatic spooling machine for elastic and non-elastic tapes

Automatic spooling machine for elastic and non-elastic tapes

-

Automatic winding machine for elastic and non-elastic tapes

Automatic winding machine for elastic and non-elastic tapes, with stapling device.

We Are Trusted

Our regular customers

-

Positive warp feeding system

Positive warp feeding systemRead more -

ITMA EXHIBITION IN MILAN 2023 CONCLUDED SUCCESSFULLY !

The ITMA exhibition, held every four years, is widely regarded as the world’s most prominent textile and garment technology showcase. It attracts exhibitors and visitors spanning various sectors of the industry, including manufacturers, suppliers and so on. Our presence at the ITMA Milan exhibition was a testament to our commitment to staying at the forefront of the industry. Our interactive booths were abuzz with excitement as visitors experienced firsthand the unrivaled quality and efficiency of our products and solutions. With the ITMA exhibition successfully concluded, we eagerly anticipate the next edition, where we will once ag...Read more